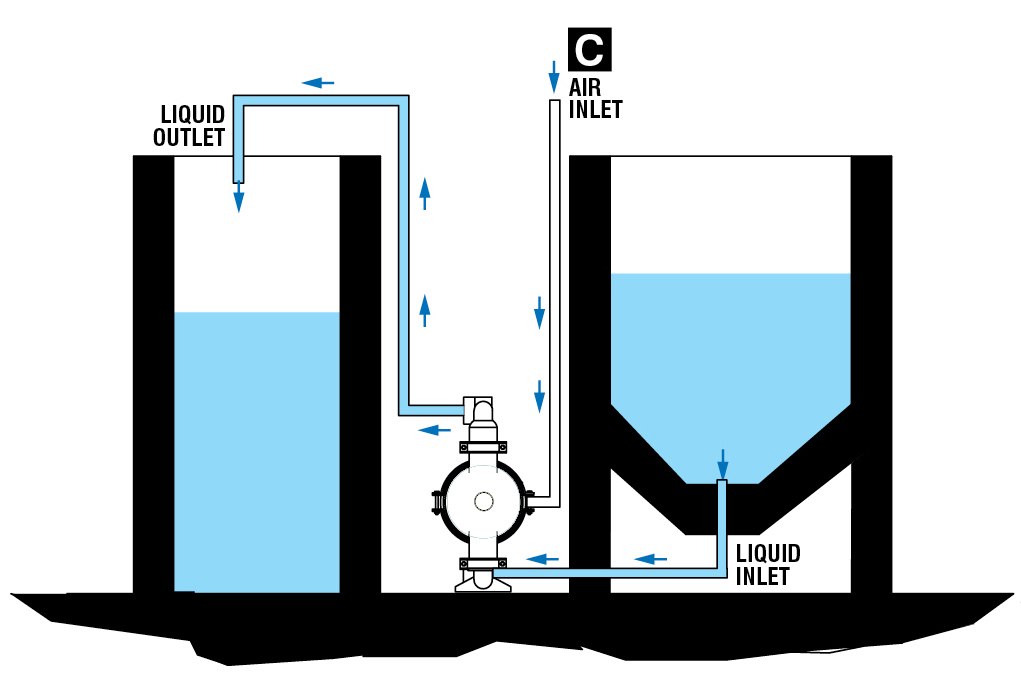

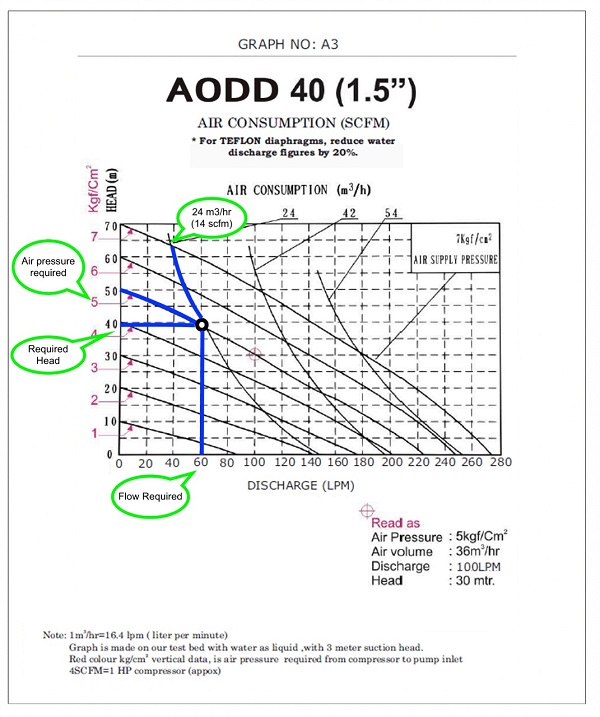

Air Operated Double Diaphragm (AODD) pumps are widely used in industrial applications because of their simplicity, safety, and ability to handle a wide range of fluids. However, correct installation and setup play a critical role in ensuring smooth operation, long service life, and consistent performance.

.jpg)

.jpg)