We at Antlia Pumps offer a variety of AODD pumps in our range. In this case, let’s consider AOD

40 in particular. This pump can transfer up to 140 liters per minute and produce 7 bars of

pressure. The diaphragm pump can be used to pump acids, solvents, paints, lubricants & other

fluids.

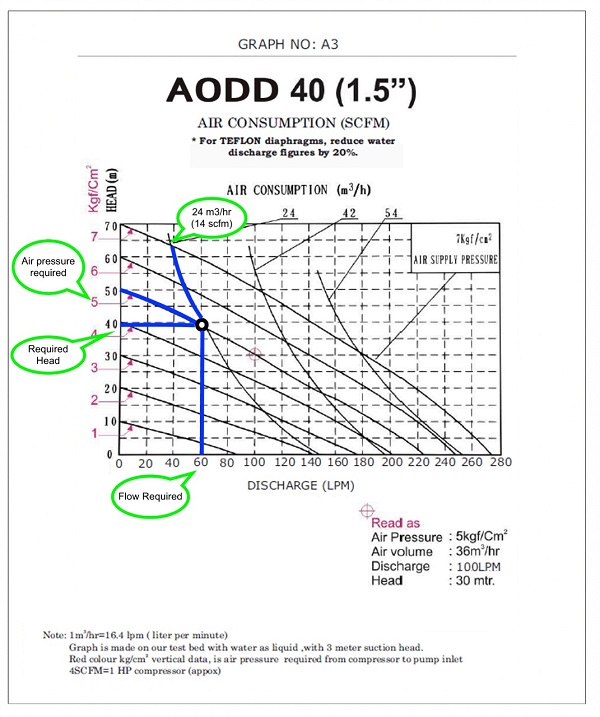

The above performance curve is for the AOD 40 model which shows required air pressure to pump a

specific volume of liquid. It looks complicated; however, with a little help it’s easy to

understand. Let’s understand the graph:

The performance curve allows you to calculate the air consumption & pressure required to move a specific volume of liquid. For example:

Looking at the performance curve of a pump you will understand what should be exactly expected of the equipment. It’s a great way to evaluate whether a pump will be the right fit.