3 FAQs about pulsation dampeners

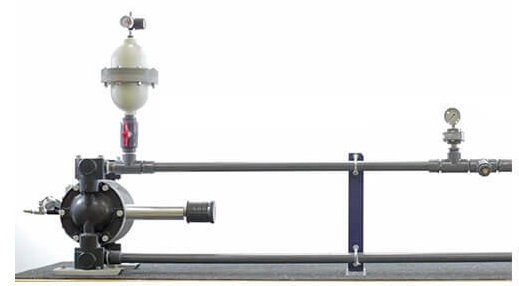

If you've got an Air operated double diaphragm pump in your system, odds are you might be experiencing some sort of pulsation resulting in the rattling and vibration movement in the pipes and system? A pulsation dampener may be a great choice for diaphragm pumps to get a steady flow.

WHAT DOES A PULSATION DAMPENER DO?

Pulsation dampeners absorb the energy from the pulse wave created by a diaphragm pump, more like a shock absorber in a vehicle. Absorbing these pulse waves protects pipe welds and supports the system components from damage due to pressure or excess movement.

HOW DOES A PULSATION DAMPENER WORK?

As the pulsating flow enters the dampener vessel, the air pocket trapped above the fluid absorbs up to 80% - 90% of the pulsation, allowing a laminar or smooth flow downstream the dampener.